Ideal icos boiler service. Today we’re going to do a service on a Ideal icos open vent heat only boiler.

It also has a HF Fault. Say Fault on Ideal Isar. NO HOT WATER, NO CENTRAL HEATING.

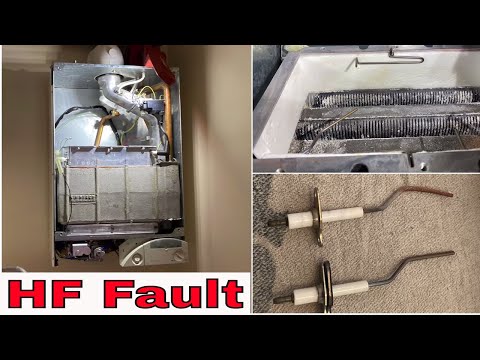

This boiler’s also got a HF fault, or an FH fault alternate. On the display it goes FH or HF. Whichever way around. And that’s normally, it could be PCB, it could be circuit board. Instructions say it could be circuit board, and it shows you how you can test for that. But it’s normally electrodes. And we’re going to change the electrodes on this job anyway. I think boiler’s about 13 or 14 years old. So it’s about time to have the electrodes done.

We’re going to strip this down and we’re going to do a full service on it. If you’re going to take a case off a boiler you must be Gas Safe registered and competent to do so. We’ve also done… There’s electrical checks on this, and they are…

They are?

What do I need to do?

Oh! Okay. So we need to turn the boiler off at the spur, and take the fuse out, keep that on you.

We did a video, didn’t we, on safe isolation?

Yeah.

But what we’re doing with this case now, with this magic pen?

Checking if it’s still-

PUP. What’s PUP mean?

PUP. PUP means is prove, use, and prove.

So we’re proving the pen works. We’re going to use the pen. And then we would prove the pen again. And that’s just a Fluke voltalert.

We just got a couple of screws underneath here to take this front cover off. And then this front cover just lifts off. And it’s the Ideal icos HE 18 kilowatt open vent boiler, or heat only boiler.

So Richard’s just removing four screws. Two on the bottom. Two on the top. And then we’re just going to take that front cover off. We’ve also got some bits for this. So we’ve got the electrode kit and then we’ve got the electrode flamesensing. And we’ve also got a new condensate trap because the other one is blocked. It’s blocked there but we’ll talk about that soon.

We’ve got a problem with this boiler. This boiler’s gurgling. And if we take these screws out of the bottom here water will come out of here because this pipe underneath… here, that pipe… is blocked. So we need to try and clear that blockage. But once we’ve done that, I’ll show you inside here. And we’re also going to change these as well.

Always read the installation and servicing instructions. And in there it’ll tell you exactly what you need to do. So we’re just going to take out this screw here. I’m going to take off that pipe there. There’s also some leads that needs unplugging on there. Careful with that. Just check all the seals. Replace, if needed. We’ve then got some screws, or bolts, or nuts at back. Three. And then three screws at front. These ones. Just that there.

And that’s your burner. Just be careful with that. And if we have a look inside there. Look at all that. So that’s the old probe there. I’m just going to change that one. So it’s all stripped down now and we’ve changed the electrodes. If this was the combi, so if this was the isar, there would be a little valve in there. I’ll just show you. There’d be a Schrader valve in the back of there and you’d pump the expansion vessel up as well. Drain the boiler. Pump the expansion vessel up. On this one it’s got a remote expansion vessel there. So, what we’re going to do, we’re going to drain it down and we’re going to pump that one up instead. And just check it.

Just going to remove these screws now and take this front cover off. We just need to clean inside there. If you can see in there, we’ve still got a puddle of water in there. And as I say this were full of water. I’ve also got some new pins because the one in the boiler snapped. So I’ve got some new pins as well. They’re in now. I have washed that through a bit, but we need to wash it a bit more. And as I always say, this should only be done by a Gas Safe registered engineer or somebody who is competent to do so. We will be testing this with all the testing equipment. We’ve got a flue gas analyzer and we’ll be testing this. So please, please do not DIY with gas. It’s just not worth it for the sake of how much it cost to get somebody who can do a good job for you. But it’s very important to get it serviced. So if you’ve got one of these boilers then please give your local gas engineer a call and get them to come and do your service.

Just put the burner back on there. We’ve still got the condensate trap to take out. We’re going to do that last. And then we’re just going to put the fan back in now. Just need to nip that back up and also tighten the fan back in. We’ve put all the leads back on. And I still need to do that trap underneath here.

We’re just going to put front cover back on now. And then that pipe up top there is where we need to check this. So that pipe on the top is where we check this one with the flue gas analyzer. So yeah.

Video