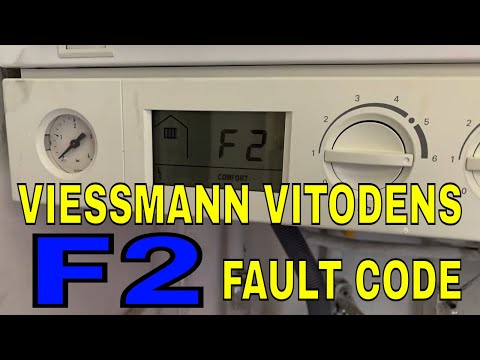

Viessmann fault code F2. Today we’ve been called out to a Viessmann Vitodens 100 and it’s got an F2 boiler fault. So what we’ll do, we’ll have a look at that, we’ll strip it down, and we’ll see what the problem is, and we’ll sort that out for the customer. After that, we’ve also got a Viessmann and it’s got an F4 fault code. So we’ll have a look at that one as well. So let’s go and have a look.

So we’ve got a Viessmann Vitodens 100 and it’s a WB1C 30 kilowatt. And this is a combi boiler and it’s got an F2 boiler fault. So what we’re going to do to start with, first of all, we’re going to take a water sample. And as you can see here, I’m just draining the water from the top of the heat exchanger and the water is really, really mucky. Because the water is so mucky in the heating system, we’re just going to drain it all down, and we’re going to check the hoses and check the plate heat exchanger.

Once you’ve drained the pressure out of the boiler, and you may do that underneath. Just to take the pressure out, you could isolate it. You could turn the flow and return off. You could drain the boiler. And once you’ve took the pressure out of the boiler, you can then check the hoses. And all you need to do is just squeeze them, just gently. Don’t start crushing him too much. If you crush them a lot, if they’re rock hard, then all the muck will go into the boiler, into the plate and bits. So you want to just be careful with them hoses. So what we’re going to do now, we’re going to take the plate heat exchanger out. We’re going to take the hoses out and we’re going to flush this through.

The biggest problem with these is muck in the heating system. Installers not flushing them correctly when they’re installed. This is the hose. If you’re going to take a case off a boiler, you must be Gas Safe registered or competent to do so. So I’m just squeezing the hose there to check them. Can’t really hear this on camera, but it’s all full. It’s all full and coated in there. What I’m going to do, I’m going to take this heat exchanger out on this and I’m going to put some new hoses on. And I’m going to clean out the heat exchanger out. I’m going to put some new hoses on this because the customer’s had a lot of problems, so I’m just going to put some new hoses in.

And what I’ve done there, I’ve just disconnected the flue off the top of the boiler, lifted it up out of the way, and then I’m going to undo … There’s a bolt back there … it’s a bit awkward to see … and one on that side. And then another one there. And I’ve just disconnected the hoses. I’m just going to disconnect that one again. And then I’m going to lift this heat exchanger out. They are quite heavy, these.

I’m also going to clean the plate heat exchanger out on this as well, while it’s out. Do a really, really good job for the customer. So remove the main heat exchanger, and what I’m going to do now is just change the hoses over. It’s not a bad job really, it’s quite easy to do. Just before we lift this plate out, don’t know if you can see there, I can see all them flakes that are in the plate, so the plate is definitely blocked on this. It’s a little bit hard to see in there, but there’s loads and loads of flakes. Loads of flakes and muck in there. Really bad.

I’ve connected this onto the outside top now. And I’m going to turn it on and we’ll see what happens. See all there? All black flakes coming out. Loads of them. Obviously they were all blocking that plate heat exchanger. I’m going to turn this on full now. I can just let that flow through. Can you see there, see how it flakes? Loads and loads of them. Obviously I’m going to wash all this off after, but that’s all muck coming out of the plate. And if I just tap it, you can see as I tap it, more and more’s coming out. And also the flow through the plate is getting greater. See the flow rate now through there, it’s coming through a lot faster than it were before.

I’ve just got some chemicals in there now, cleaning that out. I don’t know if you can see it smoking. Always remember if you’re going to work on a gas boiler, you must be Gas Safe registered or competent to do so, and you need hold the testing equipment so that when you do disturb any of the seals or the gas lines, that you can test them all afterwards. So it’s very, very important that we do not do DIY with gas. So that was the F2 fault code for the Viessmann boiler. I did add some clips in from some other boilers that I’ve been on, just so that I could show you a bit easier.

So the fault is normally, from what I’ve experienced, is you go to them, the system is normally quite mucky. Sometimes it’s not mucky, sometimes it’s clean, but normally it’s quite mucky. And the hoses, normally the hoses are rock-hard. So you took the pressure out of the boiler and the hoses are rock-hard, and they coat with the magnetite. And then when you look at the plate heat exchanger, you see